1. Related British values

1.1. Health and safety

1.1.1. Correct use of computers

1.2. Copyright laws

1.2.1. Correct use of including work created by other creators and designers

1.3. Export Licences

1.3.1. Impacts of movement mandated controls of sensitive information on how design information can be communicated

1.4. Equality and diversity

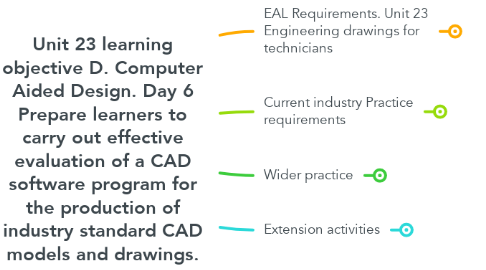

1.4.1. Considerations of presenting designs i context in a multi cultural society

2. Related application of mindfulness

2.1. Creativity

2.1.1. Open source tools for creating ideas

2.2. Self expression

2.2.1. Making descisions

2.2.2. expressing an opinion

3. Intent

4. Lesson 4

4.1. LO D Produce Models and drawings using a CAD software package

4.2. Connect

4.2.1. review current techniques used

4.2.1.1. detail current tools needed for upcoming task

4.3. Share

4.3.1. share assessment D Intent CAD modelling unit 23

4.3.1.1. Review current understanding of CAD concepts and approaches

4.4. Present

4.4.1. Tutor led modelling activity detailing final explanation prior to commencing controlled assessment

4.5. Apply

4.5.1. Learners create 2 part models

4.5.1.1. Learners build assembly

4.5.1.1.1. Learners create relevent drawings

4.6. Recap

4.6.1. Knowledge check q and a

4.6.1.1. Overview of upcoming assessments and delivery

5. Lesson 3

5.1. LO D Evaluate a computer aided design program

5.2. Connect

5.2.1. 3 question to check current learning

5.2.1.1. overview of current rendering approaches.

5.3. Share

5.3.1. Recap progress made

5.3.1.1. Knowledge check Q and A

5.4. Present

5.4.1. Teacher Demonstration showing the difference between real time and path traced renders.

5.4.1.1. 3dsmax verses Game engine tech.

5.5. Apply

5.5.1. explore the different options available for rendering Models. apply different display types to completed piston model

5.5.1.1. Learners use onshape to present the piston.

5.6. Recap

5.6.1. Knowledge check q and a

6. Lesson 2

6.1. LO D Evaluate a computer aided design program

6.2. Connect

6.2.1. Intro to rendering

6.2.1.1. Learner research activity

6.2.1.1.1. Internet research activity

6.3. Share

6.3.1. recap key points from session.

6.3.1.1. Explain current objective and activity

6.4. Present

6.4.1. Present SWOT techniques as an evaluation tool

6.4.1.1. Carry out relatable SWOT analysis

6.5. Apply

6.5.1. Work in groups of 3 to 4 to build a detailed SWOT analysis of Onshape

6.5.2. Investigate impacts of security and rendering applicable to CAD data

6.6. Recap

6.6.1. Check for learning through tutor led Q and A

7. Implementation

8. EAL Requirements. Unit 23 Engineering drawings for technicians

8.1. Learning objective D Application of CAD techniques

8.1.1. Evaluate a computer aided design program.

8.1.1.1. Software used ONSHAPE

8.1.1.2. Evaluation technique SWOT analysis

8.1.1.3. Presentation

8.1.1.4. Group activity

8.1.1.5. Individual modelling activity

8.1.1.6. Group discussion

8.1.1.7. Self evaluation

9. lesson 1

9.1. LO D Evaluate a computer aided design program

9.2. Connect

9.2.1. Introduction to 3D scanning

9.2.1.1. Learner research activity

9.2.1.1.1. Questions to answer

9.2.1.2. Resources

9.2.1.2.1. 3D scanner

9.2.1.2.2. Mind map of activity

9.2.1.2.3. Internet search

9.3. Share

9.3.1. Recap Journey so far

9.3.1.1. Share week learning plan

9.3.1.1.1. Detail the assessment schedule

9.4. Present

9.4.1. Lesson objectives presentation

9.4.1.1. Evaluate a CAD program

9.4.1.1.1. Approach

9.5. Apply

9.5.1. CAD modelling activity to refresh and recap learned topics, skills and concepts

9.5.1.1. Piston Modelling redo

9.5.1.1.1. resources

9.6. Review/ Recall

9.6.1. Q and A

9.6.1.1. SWOT analysis overview

9.6.1.2. Impact of 3D scanning on the modelling process

9.6.2. One to one review to be conducted throughout this session to establish current development opportunities

10. Current industry Practice requirements

10.1. British Standards BS 8888

10.1.1. Drawing production requirements

10.1.1.1. Correct dimensioning

10.1.1.2. First angle projection

10.2. Professional skills

10.2.1. Health and safety when using visual display equipment

10.2.1.1. effective and safe use of equipment

10.3. Professional behaviours

10.3.1. Applying acceptance criteria to produced work

10.3.1.1. Self evaluation of produced work

10.3.2. Teamwork

10.3.2.1. Group activity, SWOT analysis evaluating different aspects of ONSHAPE

10.3.3. Effective Communication within a team

10.3.3.1. Sharing ideas and experiences related to ONSHAPE to team members

11. Wider practice

11.1. Computer aided design to prototype.

11.1.1. Produce 3D printed model of designed part

11.2. Additive manufacturing techniques

11.2.1. Introduction into Design for manufacturing

11.3. Reverse engineering

11.3.1. How to apply design for manufacturing techniques and 3D printing to recrate complex parts and assemblies

11.4. Presentation and rendering

11.4.1. Introduction into modern and evolving approaches to CAD model presentation

12. Extension activities

12.1. Open source design projects

12.1.1. Build an open source robotic system using 3D printing

12.2. Impacts of CAD in virtual reality and simulation

12.2.1. Use of simulation, AI in current design pipelines for virtual engineering simulations.

12.3. Advanced photorealistic rendering

12.3.1. Current and upcoming methodology related to producing high fidelity presentations related to conveying design intent.

12.4. How coding and scripting can impact Computer aided design practice

12.4.1. Advanced modelling techniques using scripting to adjust CAD software functionality.

12.5. Introduction to 3D scanning

12.5.1. Practical set up an use of a 3D scanner

13. functional skills

13.1. Maths

13.1.1. Application of cartesian coordinated to configue complex dual material 3D printed models

13.2. English

13.2.1. Key terminology used in advanced CAD applications

13.3. ICT

13.3.1. Develop an interest in basic computer use through relatable concepts that learners are currently familiar with

13.4. Creativity

13.4.1. Use of digital design techniques and CAD as a form of self expression